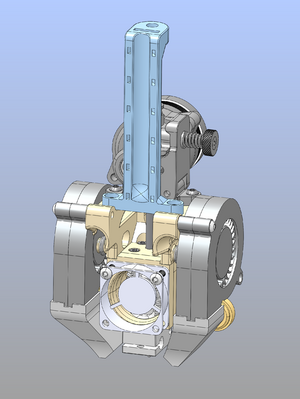

Narrow Orbiter Extruder

Orbiter extruder for a Dragon Hotend based on the E3D Tool Plate

Link to Github Reposity with latest files

https://github.com/edspeds/Dragon-Orbiter-Extruder/releases/tag/Master

Assembly Guide

Specs

- Orbiter Extruder

- E3D Tool Plate

- dual 5015 fans for extra part cooling

- ~355 grams without wiring mount

- Designed around a 4 bolt Dragon hotend

Required Parts

- E3D Tool Plate

- Orbiter Extruder

- Dragon Hotend with Groovemount adapter removed with thermistor and heater cartridge

- (2) 24V 5015 radial fans

- 30mm axial fan

- 40.5mm long piece of 4mm OD x 2mm ID PTFE tube

- (10) M3 Ultrasert II short heatserts, same as on Jubilee BOM

- (4) M2.5x8 cap screws, (typically supplied with Dragon Hotend)

- (4) M3x20 cap screws to secure hotend fan and fan shroud to mount

- (2) M3x18 cap screws (optional for lower two screws on hotend fan, I don't use to save weight)

- (4) M3x8 countersunk screws to secure mount to tool plate

- (2) M3x10 countersunk screws to secure cooling nozzle to tool plate, M3x8 will work in a pinch.

- (2) M3 hex nuts fits in cooling shroud nut pockets

- (2) M3x10 cap screws to attach orbiter to mount

- (2) M3x8 cap screws to attach harness guide to mount (if used)

- (2) 5mm x 60mm dowel rods for tool post

Printing Recommendations

- 0.2mm layer height

- Supports for O-Ring Mounts

- Brim around cooling nozzle, supports for nozzle opening are recommended but not required

- Print using material of choice though I used PETG with 6 perimeters

- 20% infill

Initial Tool Offsets

The following offsets will get you close for TAMV or whatever method you choose to use to set offsets...

X-0.789 Y32.514 Zxxx

Software Configuration

(Thanks to Poofjunior!)

Here are the general operating conditions adapted from the Orbiter Thingiverse page:

- 681 [steps/mm] (aka: "Esteps")

- 450-500 [mA] Peak Current

- 3600 [mm/min] max extrusion speed

- 600 [mm/s^2] max extrusion acceleration

- 300 [mm/min] max extrusion jerk

- 0.03 - 0.05 [sec] Pressure Advance

- 0 [mm] nominal X offset from carriage

- 32.75 [mm] nominal Y offset from carriage

- -1.23 [mm] nominal Z offset from carriage

Duet Configuration

Note that the items shown in < > signs are placeholders and should be replaced with the values you actually have. (Remove the < > signs too!)

Note that the order of many of these commands in the config matters. Example: you cannot refer to sensors or heaters in later lines of the config if they have not been created in previous lines of the config.

Define Extruder Steps/mm and Accel/Velocity Characteristics

Set the Extruder steps/mm ("Esteps") with:

M92 E681

Warning: if you have multiple extruders, you need to define them all at once like this:

M92 E681:830

In the above example, Extruder 0 has 681 steps/mm while Extruder 1 has 830 steps/mm. If your extruder steps/mm are all the same, you can just use one value, and it will apply it to all extruders.

Set the Tool's max speed, accel, and jerk (instantaneous change in velocity) with:

M201 E3600 ; Max Speed (mm/min) M203 E600 ; Max Accel (mm/s^2) M566 E300 ; Max Jerk (mm/min)

Warning: like before, if you have multiple extruders with different settings, you need to call them out individually with values separated by colons.

Define an Extruder Axis

The Duet ecosystem assumes that tools are connected to single extruder axis. Extruder axes are numbered starting from 0. Define an axis with:

M584 E1.0 ; Orbiter 0 on 3HC Board 1

The first number is the Canbus board that the motor lives on. The second number is the motor index. If you have multiple extruders, you must call them all out at once separated by colons like this:

M584 E1.0:1.1

Define a Motor Drive

Each Extruder axis needs a motor assigned to it. Assign it with

M569 P<motor_drive_index> S<1 or 0> D2

<motor_drive_index> is the same value as the E value in the M584 command.

Motor direction can be set to S0 forwards (default) or S1 backwards.

If you have additional motor drives, they each get their own line.

Assign peak motor current with:

M906 E450

Warning: like before, if you have multiple extruders with different settings, you need to set them all individually separated by colons.

Define a Temperature Sensor

The Duet ecosystem assumes that each extruder has a single temperature sensor. Define this extruder's temperature sensor index.

M308 S<sensor_index> P"1.temp0" Y"thermistor" T100000 B4725 C7.060000e-8 A"<sensor_name>"

Note that the Y"thermistor" can be other types of sensors, which may have different B and C settings--or none at all! The above settings apply to a generic E3D thermistor, usually the default in a hotend setup. There is a strict syntax of name choices that can be found in the M308 documentation.

Define a Heater

The Duet ecosystem assumes that each extruder has a single heater cartridge. Define this extruder's heater index.

M950 H<heater_index> C"1.out0" T<corresponding_temperature_sensor_index>

The C"1.out0" string encodes the Canbus board address followed by the output name. The example above creates a heater and assigns it to expansion board 1's output 0.

Define a Hotend Fan

Fans are tied to PWM based outputs on a particular board. Assign a fan with:

M950 F<fan_index> C"1.out3"

Like above, the C setting assigns the fan output from a particular board on the canbus, in this case: expansion board 1's output 3.

Additional fan settings can be configured on some outputs with the M106 command. For example:

M106 P<fan_index> S255 H<heater index> T45

assigns a heater to the fan and tells the fan not to turn on unless the heater temperature exceeds 45 degrees Celsius.

Define a Part Cooling Fan

Define a corresponding part cooling fan with:

M950 F2 C"1.out6" ; Define Part Cooling Fan output M106 P2 C"tool0_part_cooling_fan" ; Give it a schnazzy name

Define a Tool

Tools are numbered starting from 0. Define the tool index, tool name, and assign it an existing motor drive, heater, and fan:

M563 P<tool_index> S"My Chocolate Extruder" D<motor_drive_index> H<heater_index> F<part_cooling_fan_index>

Nominal Offset

Define the tool's XYZ offset from the ZProbe's trigger location. These can be set to the nominal value and adjusted later when you align tools.

G10 P<tool_index> X0 Y32.75 Z-1.23

Pressure Advance

Optional: define this extruder's pressure advance value. This can be omitted (implying a value of 0), but a value of 0.1 seems to be a good starting point for this particular extruder.

M572 D<motor_drive_index> S0.03

Klipper

TODO!