Difference between revisions of "Project Goals"

m |

Poofjunior (talk | contribs) |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 19: | Line 19: | ||

= Design Objectives = | = Design Objectives = | ||

| − | Jubilee is designed following a number of design objectives which we list here. | + | Jubilee is designed following a number of design objectives which we list here. |

| + | == Fabricatability == | ||

| + | Jubilee is designed according to a design principle that we like to call ''fabricatability.'' That is: | ||

| + | * the design should be reproducible in single quantities without relying on high volume purchases | ||

| + | * the constituent components should be broadly accessible to an international audience | ||

| + | * the design should present all necessary trade-specific knowledge up-front via documentation | ||

| + | * the design should be reproducible with commonly available unspecialized fabrication equipment | ||

| + | * the design should maximize compatibility with generic stock parts where possible | ||

Think of it as a specific flavor of ''design-for-manufacturing'' where the manufacturer is a single person, someone who may not have access to milling and turning machines or the knowledge of how to use them. This person also shouldn’t need the fine motor skills of an experienced craftsperson to assemble parts. | Think of it as a specific flavor of ''design-for-manufacturing'' where the manufacturer is a single person, someone who may not have access to milling and turning machines or the knowledge of how to use them. This person also shouldn’t need the fine motor skills of an experienced craftsperson to assemble parts. | ||

| Line 33: | Line 40: | ||

** as applied to Control Software. Jubilee should be “slicer agnostic.” Complexities such as changing tools should be encapsulated by the firmware and tool change macros. | ** as applied to Control Software. Jubilee should be “slicer agnostic.” Complexities such as changing tools should be encapsulated by the firmware and tool change macros. | ||

** as applied to separating ''application'' from ''motion interface''. Custom applications (within reason) should be possible without modifying the design of the motion system. Tools and bed plates should be the primary components that merit redesign while the frame remains mostly unchanged. | ** as applied to separating ''application'' from ''motion interface''. Custom applications (within reason) should be possible without modifying the design of the motion system. Tools and bed plates should be the primary components that merit redesign while the frame remains mostly unchanged. | ||

| + | * Provide Headway for User Customization and Common Part Alternates | ||

| + | ** minor BOM substitutions should not change overall behavior unless explicity stated otherwise. | ||

| + | *** Example: Back Panel was updated to HDPE from Acrylic, which makes it easier for extenders to modify with extra drill holes by hand. | ||

| + | *** Example: Crossbar contains lots of clearance for shoulder screws thread lengths such that shoulder screws with a variety screw thread lengths will work. | ||

| + | *** Example: All parts are specified to be printed from PLA, but details are course enough such that printing from PETG is also possible. | ||

| + | ** Conversely: avoid (or at least explicitly document) extension "gotchas." Where possible, avoid cases where a face-value equivalent substitution produce unexpected results. | ||

== Other Objectives == | == Other Objectives == | ||

| − | Apart from fabricatability, here’s a few other principles that we adhered to: * 3D printed parts should minimize the use of support material * 3D printed parts should avoid | + | Apart from fabricatability, here’s a few other principles that we adhered to: |

| + | * Adhere to [https://en.wikipedia.org/wiki/Poka-yoke#:~:text=Poka%2Dyoke%20(%E3%83%9D%E3%82%AB%E3%83%A8%E3%82%B1%2C%20%5B,yokeru)%20mistakes%20(poka). Poka Yoke] ("mistake-proofing") principles where possible in cases involving user assembly, modification, and extension to custom applications. | ||

| + | * 3D printed parts should minimize the use of support material | ||

| + | * 3D printed parts should avoid support material on features where dimensional accuracy is required | ||

| + | * 3D printed parts should be simple enough to print correctly on a broad range of affordable (under $1000) printers. | ||

| + | * the hardware design should be reproducible to the same level of fidelity by both novice and expert without relying on knowledge outside the documentation. External references are OK, however. | ||

| + | * Dimensional accuracy should be achieved through (1) ''exact constraint design principles'', (2) a reliable manufacturing process, or (3) measurement/alignment tools, but not through the motor skills or judgment of the assembler. | ||

| + | * As a restatement from above: where possible, parts should fit together ''digitally''. That is, features where parts connect together should fully constrain both parts such that they do not require fine tuning to seat in their proper positions. | ||

== Shopping List Objectives == | == Shopping List Objectives == | ||

Latest revision as of 17:06, 28 July 2020

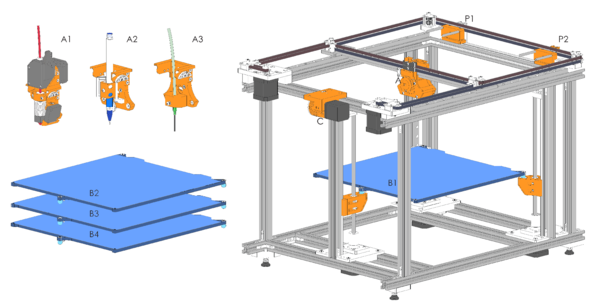

The Jubilee project is intended to provide an open-source, extensible motion platform to anyone who puts the time into building one. It does so in two ways: (1) through a highly reliable toolchanging system and (2) through a hot-swappable bed platform. In this sense, Jubilee isn’t just a multimaterial 3D printer, but more so an API for motion, a platform extensible enough to solve a range of non-loadbearing automation applications.

Jubilee’s design is intended to be straightforward to assemble and readily extensible such that machine builders of all skill levels can enjoy the capabilities of automatic toolchanging. The design is kept as simple as possible without sacrificing performance or reliability. As the project grows, many of Jubilee’s parts will get upgrades that either reduce machine maintenance or add features on top of the base Jubilee. See the [project timeline] and check in on Discord for all the “coming-soon” features!

A Reference Design

Jubilee is intended to encapsulate a collection of good design practices from the community of open source machine designers. It is a reference design that showcases patterns and practices that work well for anyone designing high fidelity prototypes that make use of makerspace-like tooling. On that note, if you find inconsistencies and points of confusion, please submit an issue or chat with fellow community builders on Discord.

A Common Tool Library via a New Open Standard

Jubilee’s toolchanger is designed to be compatible with E3D’s tool plates with the intent of establishing a library of interchangeable tools across a range of printers. Striving for a common standard makes the most of community efforts to create new heads since a tool’s target hardware is broad, not specific.

One Size Fits Most

We recognize that Jubilee, as designed, can’t quite accommodate everyone’s particular tastes, from size requirements to control boards. We welcome others to customize the design files to their liking and share their Modified Jubilees (aka Modulees) or Jubilee-inspired machines.

Design Objectives

Jubilee is designed following a number of design objectives which we list here.

Fabricatability

Jubilee is designed according to a design principle that we like to call fabricatability. That is:

- the design should be reproducible in single quantities without relying on high volume purchases

- the constituent components should be broadly accessible to an international audience

- the design should present all necessary trade-specific knowledge up-front via documentation

- the design should be reproducible with commonly available unspecialized fabrication equipment

- the design should maximize compatibility with generic stock parts where possible

Think of it as a specific flavor of design-for-manufacturing where the manufacturer is a single person, someone who may not have access to milling and turning machines or the knowledge of how to use them. This person also shouldn’t need the fine motor skills of an experienced craftsperson to assemble parts.

Usability and Extensibility

- Maintain a consistent Conceptual Model of the project across all content sources

- Parts should be referred to consistently in the BOM, instructions, and when engaging people on chat channels.

- Minimize Cognitive Overhead, the thinking burden placed on the user to understand how something maps to the other.

- Assembly instructions should be broken down step-by-step in a way that seems logically consistent. (In video editing terms, no jump cuts.)

- Assembly instructions should be stylized consistently

- Separation of Concerns

- as applied to Control Software. Jubilee should be “slicer agnostic.” Complexities such as changing tools should be encapsulated by the firmware and tool change macros.

- as applied to separating application from motion interface. Custom applications (within reason) should be possible without modifying the design of the motion system. Tools and bed plates should be the primary components that merit redesign while the frame remains mostly unchanged.

- Provide Headway for User Customization and Common Part Alternates

- minor BOM substitutions should not change overall behavior unless explicity stated otherwise.

- Example: Back Panel was updated to HDPE from Acrylic, which makes it easier for extenders to modify with extra drill holes by hand.

- Example: Crossbar contains lots of clearance for shoulder screws thread lengths such that shoulder screws with a variety screw thread lengths will work.

- Example: All parts are specified to be printed from PLA, but details are course enough such that printing from PETG is also possible.

- Conversely: avoid (or at least explicitly document) extension "gotchas." Where possible, avoid cases where a face-value equivalent substitution produce unexpected results.

- minor BOM substitutions should not change overall behavior unless explicity stated otherwise.

Other Objectives

Apart from fabricatability, here’s a few other principles that we adhered to:

- Adhere to Poka Yoke ("mistake-proofing") principles where possible in cases involving user assembly, modification, and extension to custom applications.

- 3D printed parts should minimize the use of support material

- 3D printed parts should avoid support material on features where dimensional accuracy is required

- 3D printed parts should be simple enough to print correctly on a broad range of affordable (under $1000) printers.

- the hardware design should be reproducible to the same level of fidelity by both novice and expert without relying on knowledge outside the documentation. External references are OK, however.

- Dimensional accuracy should be achieved through (1) exact constraint design principles, (2) a reliable manufacturing process, or (3) measurement/alignment tools, but not through the motor skills or judgment of the assembler.

- As a restatement from above: where possible, parts should fit together digitally. That is, features where parts connect together should fully constrain both parts such that they do not require fine tuning to seat in their proper positions.

Shopping List Objectives

- the shopping list should supports builders from many regions

- the shopping list should be kept up-to-date with the latest stable version of Jubilee

- the shopping list should be easy to maintain and kept up-to-date

Exceptions

Nothing is perfect! And Jubilee has a few minor exceptions to the guidelines above. Specifically, three parts must be machined with metalworking tools. While these processes do increase the expertise level and barrier to entry, we’ve found a small collection of community machinists who will make these parts for you at an affordable price. See the Parts to Machine (or buy) section for details on how to buy these parts, rather than make them yourself.