Difference between revisions of "ASMBL"

| Line 11: | Line 11: | ||

=Milling/Engraving Workflow= | =Milling/Engraving Workflow= | ||

| − | The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely | + | The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely gets caught under the milling bit, and then noting the x, y, and z offsets. These can then be placed into the current workspace offset with G10 L2 P1 X_offset Y_offset Z_offset. Once this has been accomplished a gcode cam path can be uploaded and started. |

Revision as of 08:35, 1 June 2021

Additive Subtractive Manufacturing By Layer

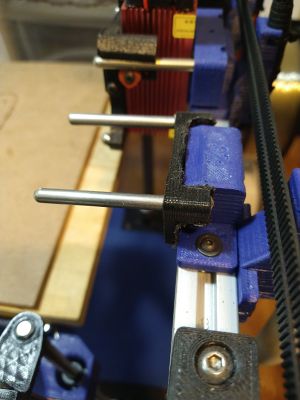

The ASMBL tool is a brushless DC motor driven spindle, controlled through a RC electronic speed controller. This is driven by the Duex5 board on a PWM pin established in the config.g and Fusion 360 post processor. The tool is attached to the Jubilee via a modified toolpost. A a 20mm vacuum line and vacuum is attached to the ASMBL for chip removal.

ESC Configuration

Update in progress

Fusion 360 Post Processor

Update in progress

Tool Post

Milling/Engraving Workflow

The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely gets caught under the milling bit, and then noting the x, y, and z offsets. These can then be placed into the current workspace offset with G10 L2 P1 X_offset Y_offset Z_offset. Once this has been accomplished a gcode cam path can be uploaded and started.