Difference between revisions of "Bondtech Direct Drive Extruder"

Poofjunior (talk | contribs) (→Wiring) |

Poofjunior (talk | contribs) |

||

| (27 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

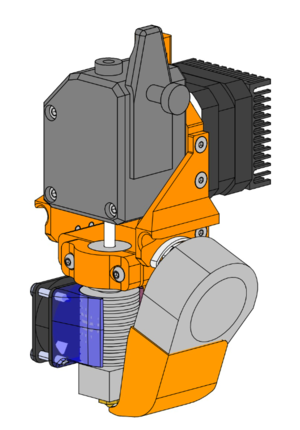

[[File:Bondtech direct drive extruder.png|thumb]] | [[File:Bondtech direct drive extruder.png|thumb]] | ||

| − | This is the default extruder. It’s compatible with both an E3D V6 and an E3D Volcano hotend. This extruder will work with the fabrications specs below with nozzle temps up to 250C and a bed plate temperature up to 80C. | + | This is the old default extruder (now superseded by the [[Baby Bullet Extruder]]). |

| + | It’s compatible with both an E3D V6 and an E3D Volcano hotend. This extruder will work with the fabrications specs below with nozzle temps up to 250C and a bed plate temperature up to 80C. | ||

Note: motor heatsinks are not optional! If you operate the motors without heatsinks, the tool plates will warp from the heat. Exposure to radiated heat from the nozzle and the bed is fine up to 80C | Note: motor heatsinks are not optional! If you operate the motors without heatsinks, the tool plates will warp from the heat. Exposure to radiated heat from the nozzle and the bed is fine up to 80C | ||

| Line 12: | Line 13: | ||

* 1x [https://www.filastruder.com/collections/e3d-spare-parts-and-accessories/products/capricorn-tubing-cutter PTFE Tube Cutter] | * 1x [https://www.filastruder.com/collections/e3d-spare-parts-and-accessories/products/capricorn-tubing-cutter PTFE Tube Cutter] | ||

* 1x [https://www.filastruder.com/products/e3d-nozzle-spanner-wrench?variant=3382501700 E3D Nozzle Spanner Wrench] | * 1x [https://www.filastruder.com/products/e3d-nozzle-spanner-wrench?variant=3382501700 E3D Nozzle Spanner Wrench] | ||

| + | * [https://www.amazon.com/Weller-SP40NUS-40-Watt-Soldering-Iron/dp/B00B3SG6UQ Budget Soldering Iron] for installing heat-set inserts | ||

| + | ** Recommended: [https://www.mcmaster.com/92160a115 Heat-Set Insert Installation Tip]. This one will work for M3 and M4 inserts. | ||

== 3D Printed Parts and Settings == | == 3D Printed Parts and Settings == | ||

| Line 27: | Line 30: | ||

* [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/blower_fan_shroud.STL Blower Fan Shroud] | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/blower_fan_shroud.STL Blower Fan Shroud] | ||

| − | |||

* [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/tool_plate.STL Tool Plate] | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/tool_plate.STL Tool Plate] | ||

** 100% infill (yeup, solid) | ** 100% infill (yeup, solid) | ||

| Line 34: | Line 36: | ||

* [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/left_parking_wing.STL Left Parking Wing] | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/left_parking_wing.STL Left Parking Wing] | ||

* [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/right_parking_wing.STL Right Parking Wing] | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/right_parking_wing.STL Right Parking Wing] | ||

| − | + | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/ooze_wipers/fabrication_exports/ooze_wiper.STL Ooze Wiper] | |

| − | |||

| − | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/ | ||

* [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/tool_cable_management_bracket.STL Tool Cable Management Bracket] | * [https://github.com/machineagency/jubilee/blob/master/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/fabrication_exports/tool_cable_management_bracket.STL Tool Cable Management Bracket] | ||

| − | * [https://github.com/machineagency/jubilee/blob/ | + | * [https://github.com/machineagency/jubilee/blob/main/tools/jubilee_tools/tool_posts/configurable_tool_post/fabrication_exports/parking_post_base_2655.STL Parking Post Base 26 x 55] |

| − | * [https://github.com/machineagency/jubilee/blob/ | + | * [https://github.com/machineagency/jubilee/blob/main/tools/jubilee_tools/tool_posts/configurable_tool_post/fabrication_exports/tool_holder_2655.STL Tool Holder 26 x 55] |

== Assembly Instructions == | == Assembly Instructions == | ||

| − | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/ | + | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/main/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/assembly_instructions/bondtech_groovemount_extruder_assembly_instructions.pdf Tool Assembly Instructions] |

| − | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/ | + | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/main/tools/jubilee_tools/tool_posts/configurable_tool_post/assembly_instructions/parking_post_assembly_instructions.pdf Parking Post Assembly Instructions] |

| + | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/main/tools/jubilee_tools/tools/extruders/ooze_wipers/documentation/ooze_wiper_assembly.pdf Ooze Wiper Assembly Instructions] | ||

== Wiring == | == Wiring == | ||

| − | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/ | + | [[File:Tool Wiring Step.jpg|thumb]] |

| + | There are many ways to wire Jubilee tools, so feel free to take the option below as a suggestion. | ||

| + | * [https://docs.google.com/viewer?url=https://github.com/machineagency/jubilee/raw/main/tools/jubilee_tools/tools/extruders/direct_drive_bondtech_groovemount_extruder/assembly_instructions/wiring/duet2_bondtech_default_tool_wiring.pdf Default Wiring Diagram] and [https://www.aliexpress.com/item/1005002022882161.html Purchase Option] | ||

| + | ** Please note: the Blurolls Purchase Option ''has several errors'', but they can be corrected with far less hassle then making a harness from scratch. See the [[Blurolls Wiring Harness Errata]] page for more details. | ||

| + | |||

| + | [[File:Extruder to Duet.png|thumb]] | ||

| + | |||

| + | Note that these wires are rather long because they must loop over the frame in an arch fashion and then return under the frame to the back of the machine where they are plugged into the control boards. | ||

| + | |||

| + | The image on the right shows how to wire tool1 (Extruder 0, E0) to the Duet. | ||

| + | |||

| + | ===Duet3 Note=== | ||

| + | Because some slicers send a command to turn off fans at the start of a print (M107) and because that command defaults to fan 0, we recommend '''not''' wiring the hotend (heatsink) fan to fan port 0 on the Duet 3 6HC board. For more info, see [https://forum.duet3d.com/topic/18783/prusaslicer-m107-start-code-disabling-thermostatic-extruder-fan/11?_=1600897890900 this duet forum post]. | ||

| + | |||

| + | == Software Configuration == | ||

| + | Here are the general settings | ||

| + | * 830 [steps/mm] (aka: "Esteps") | ||

| + | * 1250 [mA] Extruder Motor Peak Current | ||

| + | * 0.0 - 0.05 [sec] Pressure Advance | ||

| + | * -5.36 [mm] nominal X offset from [[The Control Point]] on the carriage | ||

| + | * 44.7 [mm] nominal Y offset from [[The Control Point]] on the carriage | ||

| + | * -2.25 [mm] nominal Z offset from [[The Control Point]] on the carriage | ||

| + | |||

| + | Note that your XYZ offsets will be slightly different per tool, and that these values are nominal values (as measured from the CAD model). | ||

| + | |||

| + | ===Duet 2 or 3=== | ||

| + | Note that the items shown in ''< >'' signs are placeholders and should be replaced with the values you actually have. (Remove the ''< >'' signs too!) | ||

| + | |||

| + | The Duet ecosystem assumes that tools are connected to single motor drive. Motor drives are numbered starting from 0. | ||

| + | Define a motor drive with: | ||

| + | <pre> | ||

| + | M569 P<motor_drive_index> S0 | ||

| + | </pre> | ||

| + | (S1 inverts the direction of the motor drive.) | ||

| + | |||

| + | Tools are numbered starting from 0. Define the tool index, tool name, and connect the motor drive that will control it with: | ||

| + | <pre> | ||

| + | M563 P<tool_index> S"My Chocolate Extruder" D<motor_drive_index> H1 F0 | ||

| + | </pre> | ||

| + | |||

| + | Define the [[Setting_Tool_Offsets|tool offset]] from the ZProbe trigger location. These can be set to all zero for now and set later. | ||

| + | <pre> | ||

| + | G10 P<tool_index> X-4.5 Y44.02 Z-2.25 | ||

| + | </pre> | ||

| + | |||

| + | ''Optional'': define the default operating and standby temperatures. These can be omitted since most 3D Printer Slicer programs will set these at the start of the print. | ||

| + | <pre> | ||

| + | G10 P0 S<extruding_temperature> R<standby_temperature> | ||

| + | </pre> | ||

| + | |||

| + | ''Optional'': define this extruder's ''pressure advance'' value. This can be omitted (implying a value of 0), but a value of 0.1 seems to be a good starting point for this particular extruder. | ||

| + | |||

| + | Use https://github.com/Treysen-Zobell/PressureAdvanceGenerator to calibrate each filament. | ||

| + | <pre> | ||

| + | M572 D<motor_drive_index> S0.1 | ||

| + | </pre> | ||

| + | |||

| + | The Duet ecosystem assumes that each extruder has a single temperature sensor. | ||

| + | Define this extruder's temperature sensor index. | ||

| + | <pre> | ||

| + | TODO | ||

| + | </pre> | ||

| + | |||

| + | The Duet ecosystem assumes that each extruder has a single heater cartridge. | ||

| + | Define this extruder's temperature sensor index. | ||

| + | <pre> | ||

| + | TODO | ||

| + | </pre> | ||

| + | |||

| + | Put all these lines of code in your config file. | ||

| + | ===Klipper=== | ||

| + | Not yet implemented | ||

| + | |||

| + | ==Provisioning== | ||

| + | * [[Setting Tool Parking Positions]] | ||

| + | * [[Extruder Heater Tuning]] | ||

| + | * Hot-Tightening | ||

| + | ** With the heater tuned, you can now set the temperature and [https://www.matterhackers.com/articles/how-to-assemble-an-e3d-v6-all-metal-hotend hot-tighten] the nozzle. | ||

Latest revision as of 21:35, 2 February 2022

This is the old default extruder (now superseded by the Baby Bullet Extruder). It’s compatible with both an E3D V6 and an E3D Volcano hotend. This extruder will work with the fabrications specs below with nozzle temps up to 250C and a bed plate temperature up to 80C.

Note: motor heatsinks are not optional! If you operate the motors without heatsinks, the tool plates will warp from the heat. Exposure to radiated heat from the nozzle and the bed is fine up to 80C

Parts to Buy

For a set of two extruders, all parts to buy are called out in this spreadsheet tab.

Assembly Tools

- 1x PTFE Tube Cutter

- 1x E3D Nozzle Spanner Wrench

- Budget Soldering Iron for installing heat-set inserts

- Recommended: Heat-Set Insert Installation Tip. This one will work for M3 and M4 inserts.

3D Printed Parts and Settings

Common Settings

- PLA

- 0.4mm nozzle

- No supports

- 0.2mm layer height

- 6 perimters

- 20% infill (any pattern)

Parts and Special Settings

- Blower Fan Shroud

- Tool Plate

- 100% infill (yeup, solid)

- Extruder Holder

- Groovemount Clip

- Left Parking Wing

- Right Parking Wing

- Ooze Wiper

- Tool Cable Management Bracket

- Parking Post Base 26 x 55

- Tool Holder 26 x 55

Assembly Instructions

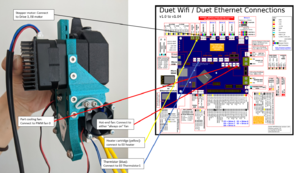

Wiring

There are many ways to wire Jubilee tools, so feel free to take the option below as a suggestion.

- Default Wiring Diagram and Purchase Option

- Please note: the Blurolls Purchase Option has several errors, but they can be corrected with far less hassle then making a harness from scratch. See the Blurolls Wiring Harness Errata page for more details.

Note that these wires are rather long because they must loop over the frame in an arch fashion and then return under the frame to the back of the machine where they are plugged into the control boards.

The image on the right shows how to wire tool1 (Extruder 0, E0) to the Duet.

Duet3 Note

Because some slicers send a command to turn off fans at the start of a print (M107) and because that command defaults to fan 0, we recommend not wiring the hotend (heatsink) fan to fan port 0 on the Duet 3 6HC board. For more info, see this duet forum post.

Software Configuration

Here are the general settings

- 830 [steps/mm] (aka: "Esteps")

- 1250 [mA] Extruder Motor Peak Current

- 0.0 - 0.05 [sec] Pressure Advance

- -5.36 [mm] nominal X offset from The Control Point on the carriage

- 44.7 [mm] nominal Y offset from The Control Point on the carriage

- -2.25 [mm] nominal Z offset from The Control Point on the carriage

Note that your XYZ offsets will be slightly different per tool, and that these values are nominal values (as measured from the CAD model).

Duet 2 or 3

Note that the items shown in < > signs are placeholders and should be replaced with the values you actually have. (Remove the < > signs too!)

The Duet ecosystem assumes that tools are connected to single motor drive. Motor drives are numbered starting from 0. Define a motor drive with:

M569 P<motor_drive_index> S0

(S1 inverts the direction of the motor drive.)

Tools are numbered starting from 0. Define the tool index, tool name, and connect the motor drive that will control it with:

M563 P<tool_index> S"My Chocolate Extruder" D<motor_drive_index> H1 F0

Define the tool offset from the ZProbe trigger location. These can be set to all zero for now and set later.

G10 P<tool_index> X-4.5 Y44.02 Z-2.25

Optional: define the default operating and standby temperatures. These can be omitted since most 3D Printer Slicer programs will set these at the start of the print.

G10 P0 S<extruding_temperature> R<standby_temperature>

Optional: define this extruder's pressure advance value. This can be omitted (implying a value of 0), but a value of 0.1 seems to be a good starting point for this particular extruder.

Use https://github.com/Treysen-Zobell/PressureAdvanceGenerator to calibrate each filament.

M572 D<motor_drive_index> S0.1

The Duet ecosystem assumes that each extruder has a single temperature sensor. Define this extruder's temperature sensor index.

TODO

The Duet ecosystem assumes that each extruder has a single heater cartridge. Define this extruder's temperature sensor index.

TODO

Put all these lines of code in your config file.

Klipper

Not yet implemented

Provisioning

- Setting Tool Parking Positions

- Extruder Heater Tuning

- Hot-Tightening

- With the heater tuned, you can now set the temperature and hot-tighten the nozzle.