Difference between revisions of "ASMBL"

m (→Tips) |

|||

| (7 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

==Additive Subtractive Manufacturing By Layer== | ==Additive Subtractive Manufacturing By Layer== | ||

The ASMBL tool is a brushless DC motor driven spindle, controlled through a RC electronic speed controller. This is driven by the Duex5 board on a PWM pin established in the config.g and Fusion 360 post processor. The tool is attached to the Jubilee via a modified toolpost. A a 20mm vacuum line and vacuum is attached to the ASMBL for chip removal.[[File:ASMBL.jpg|thumb]] | The ASMBL tool is a brushless DC motor driven spindle, controlled through a RC electronic speed controller. This is driven by the Duex5 board on a PWM pin established in the config.g and Fusion 360 post processor. The tool is attached to the Jubilee via a modified toolpost. A a 20mm vacuum line and vacuum is attached to the ASMBL for chip removal.[[File:ASMBL.jpg|thumb]] | ||

| + | |||

| + | The Andy Everitt github for original ASMBL documentation | ||

| + | |||

| + | https://github.com/AndyEveritt/ASMBL | ||

=ESC Configuration= | =ESC Configuration= | ||

| Line 8: | Line 12: | ||

Fusion 360 post processor | Fusion 360 post processor | ||

| + | |||

https://drive.google.com/file/d/1gr_61fRjwU8bOqlmvmMZSqkLpUUynF5l/view?usp=sharing | https://drive.google.com/file/d/1gr_61fRjwU8bOqlmvmMZSqkLpUUynF5l/view?usp=sharing | ||

| Line 15: | Line 20: | ||

=Milling/Engraving Workflow= | =Milling/Engraving Workflow= | ||

| − | The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely gets caught under the milling bit, and then noting the x, y, and z offsets. These can then be placed into the current workspace offset with G10 L2 P1 X_offset Y_offset Z_offset. Once this has been accomplished a gcode cam path can be uploaded and started. | + | The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely gets caught under the milling bit, and then noting the x, y, and z offsets. These can then be placed into the current workspace offset with <code>G10 L2 P1 X_offset Y_offset Z_offset</code>. Once this has been accomplished a gcode cam path can be uploaded and started. |

| + | |||

| + | =Notes on ESCs= | ||

| + | ESCs generally use pulse widths between 1000us and 2000us to control the speed of BLDC motors. This is the range that RC radios use when communicating to electronics, too and correspond to the low, and high signals that a BLDC ESC will expect from an arming or programming sequence. | ||

| + | |||

| + | ESCs have a decent amount of logic onboard and will generally need an arming sequence in order to be used during a print. For ESCs using BLHeli the arming sequence is a low throttle signal. | ||

| + | |||

| + | = Configuring Duet Firmware for ESCs= | ||

| + | One option for configuring ESCs is below. A servo isn't defined, and a GPIO pin is defined as if you define a servo, it can be difficult to prevent the ESC from beeping after a couple minutes of a low throttle signal. | ||

| + | |||

| + | |||

| + | Add to the config.g file: | ||

| + | <pre> | ||

| + | ; Define Tool 1 for ASMBL | ||

| + | M563 P1 S"ASMBL" | ||

| + | |||

| + | M950 P5 C"io4.out" ; definition for GPIO on pin #4 (On Duet3 this is a PWM capable pin) | ||

| + | M42 P5 S0.5 ; Low throttle equivalent signal to ESC | ||

| + | G4 S3 ; Need to wait more than 2 sec after initialization after power on of the ESC or else the ESC enters program mode | ||

| + | M42 P5 S0 ; Setting the ESC PWM input pin to this value prevents ESC from beeping continually when not in use. | ||

| + | |||

| + | ; Send a M42 P5 S0.6 command to spin motor at low speed | ||

| + | ; Send a M42 P5 S0.9 command to spin motor at high speed | ||

| + | </pre> | ||

| + | |||

| + | =Tips= | ||

| + | * Make sure you are using a PWM compatible pin with the ESC controller | ||

| + | * 4S motors and ESCs can use 12V PSU, 6S motors and ESCs can use a 24V PSU | ||

| + | * Make sure to "tie" the negative leads of both PSUs (if using multiple, like a 12V PSU for the ESC and a 24V for the printer) together and to ground in order to make sure that the signals are referenced to the same ground level | ||

| + | * ESCs using BLHeli firmware are known to work | ||

| + | * To easily change the direction the BLDC spins, swap 2 of the 3 motor wires that go to the ESC | ||

Latest revision as of 18:06, 24 May 2022

Additive Subtractive Manufacturing By Layer

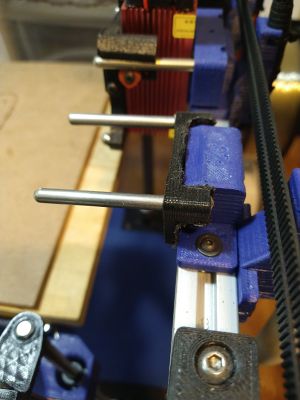

The ASMBL tool is a brushless DC motor driven spindle, controlled through a RC electronic speed controller. This is driven by the Duex5 board on a PWM pin established in the config.g and Fusion 360 post processor. The tool is attached to the Jubilee via a modified toolpost. A a 20mm vacuum line and vacuum is attached to the ASMBL for chip removal.

The Andy Everitt github for original ASMBL documentation

https://github.com/AndyEveritt/ASMBL

ESC Configuration

Update in progress

Fusion 360 Post Processor

Update in progress

Fusion 360 post processor

https://drive.google.com/file/d/1gr_61fRjwU8bOqlmvmMZSqkLpUUynF5l/view?usp=sharing

Tool Post

Milling/Engraving Workflow

The origin must be correctly placed on the top of the stock to mill/engrave prior to operation. This can be easily accomplished by jogging the tool to the desired location, raising the z height such that a piece of paper just barely gets caught under the milling bit, and then noting the x, y, and z offsets. These can then be placed into the current workspace offset with G10 L2 P1 X_offset Y_offset Z_offset. Once this has been accomplished a gcode cam path can be uploaded and started.

Notes on ESCs

ESCs generally use pulse widths between 1000us and 2000us to control the speed of BLDC motors. This is the range that RC radios use when communicating to electronics, too and correspond to the low, and high signals that a BLDC ESC will expect from an arming or programming sequence.

ESCs have a decent amount of logic onboard and will generally need an arming sequence in order to be used during a print. For ESCs using BLHeli the arming sequence is a low throttle signal.

Configuring Duet Firmware for ESCs

One option for configuring ESCs is below. A servo isn't defined, and a GPIO pin is defined as if you define a servo, it can be difficult to prevent the ESC from beeping after a couple minutes of a low throttle signal.

Add to the config.g file:

; Define Tool 1 for ASMBL M563 P1 S"ASMBL" M950 P5 C"io4.out" ; definition for GPIO on pin #4 (On Duet3 this is a PWM capable pin) M42 P5 S0.5 ; Low throttle equivalent signal to ESC G4 S3 ; Need to wait more than 2 sec after initialization after power on of the ESC or else the ESC enters program mode M42 P5 S0 ; Setting the ESC PWM input pin to this value prevents ESC from beeping continually when not in use. ; Send a M42 P5 S0.6 command to spin motor at low speed ; Send a M42 P5 S0.9 command to spin motor at high speed

Tips

- Make sure you are using a PWM compatible pin with the ESC controller

- 4S motors and ESCs can use 12V PSU, 6S motors and ESCs can use a 24V PSU

- Make sure to "tie" the negative leads of both PSUs (if using multiple, like a 12V PSU for the ESC and a 24V for the printer) together and to ground in order to make sure that the signals are referenced to the same ground level

- ESCs using BLHeli firmware are known to work

- To easily change the direction the BLDC spins, swap 2 of the 3 motor wires that go to the ESC