Difference between revisions of "Specs"

Jump to navigation

Jump to search

Poofjunior (talk | contribs) |

Poofjunior (talk | contribs) |

||

| Line 34: | Line 34: | ||

== How it Works == | == How it Works == | ||

| − | Read more about Jubilee's subsystem design in the links below: | + | Read more about Jubilee's subsystem design and intended software behaviors in the links below: |

| + | |||

| + | ===Hardware Design=== | ||

* [[Locating_Tools]] | * [[Locating_Tools]] | ||

* [[The_Remote_Elastic_Lock]] | * [[The_Remote_Elastic_Lock]] | ||

* [[A Kinematically Coupled Bed]] | * [[A Kinematically Coupled Bed]] | ||

| + | |||

| + | ===Softare Behaviors=== | ||

| + | * [[Changing Tools]] | ||

== Pricing == | == Pricing == | ||

Revision as of 20:12, 4 July 2020

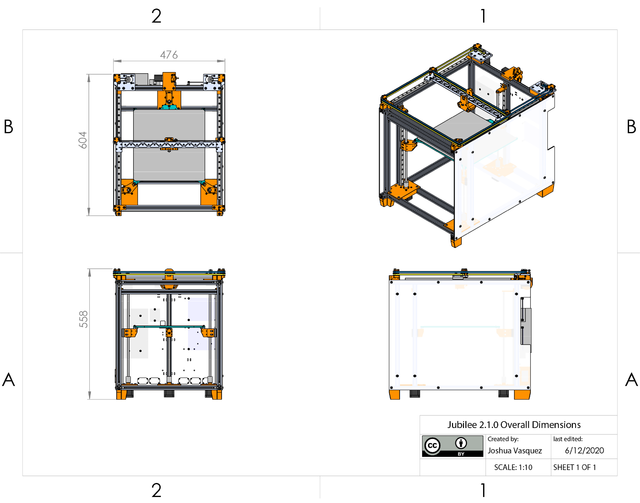

The following specs apply to the latest 2.1.x version of Jubilee. For a play-by-play view of changes across versions, see the Changelog.

Mechanical Motion System Design

- 300x300x300mm build space (with the default extruder). See the Build Volume Tool Relationship page for how tools change the effective build volume.

- All purchased parts called out in the V2 Shopping List.

- Designed such that the Z-axis can be adjusted to your liking with no changes to the XY frame or toolchanging setup.

- Core-XY layout for high-speed printing. Rapids of between 20000mm/min and 30000 mm/min depending on XY stepper motors and heatsinking options.

- Flush-Form CoreXY Belt Pattern. Upper and lower belts are laid out directly on top of each other, and belts only travel perpendicular to the frame. Belt-tensioning is done conveniently with two set-screws that adjust the motor locations along slots.

- Designed with Exact-Constraint machine-design principles where possible

- Kinematically coupled bed plate

- autotramming with 3-point bed-leveling (courtesy of the Duet)

- *Fabricatable.* Almost all fabricated parts are 3D printable. Printed parts are intentionally kept simple and minimize the use of support material. (Exceptions: the bed plate, crossbar, and toolchanger lock must be machined. See notes in the BOM for getting these parts made for cheap.)

- Metric fasteners everywhere.

- Documented with a comprehensive BOM and set of assembly instructions.

Tools and Tool-Changing

- 409mm of horizontal tool rack space, capable of holding 4 default extruder tools

- Detailed Space Specifications for adding custom tools presented in the Tool Interface Diagram (PDF).

- Automatic Toolchanging System compatible with both homebrew and E3D tool plates

- Sensored, torque-based locking system will lock down tool plates with a constant locking torque.

3D Printing

- Stellar print quality with direct-drive extruders. Jubilee can compete with systems at the $5K price range.

- Multicolor Printing possible *without* the need for a prime tower made possible by firmware-driven purge and wipe commands between tool changes. (This feature requires quite a bit of tuning to get working.)

- Slicer-agnostic. All the complexity of juggling tools is handled at the GCode firmware script level. Slicers need only change to a new tool by invoking a *T0*, *T1*, etc. command.

Extensibility

- User Extensible! Jubilee can accommodate custom tools and custom bed plates for specialized 3D-printing and uses beyond 3D printing. (See the Extending section)

Testing

- Cycle-tested. Jubilee has performed thousands of toolchanges flawlessly.

How it Works

Read more about Jubilee's subsystem design and intended software behaviors in the links below:

Hardware Design

Softare Behaviors

Pricing

- Self-Sourcing parts for Jubilee cost ~$1400 (US). The default extruder costs ~$200 each. We encourage community development for a wider spread of tools at different price points.

Legal

- Completely Open-Source with a CC-BY license. STLs, STEPs, and original Solidworks assemblies are included in the online project repository. Make use of the Jubilee design in ways that suit you.