Specs

The following specs apply to the latest 2.1.x version of Jubilee. For a play-by-play view of changes across versions, see the Changelog.

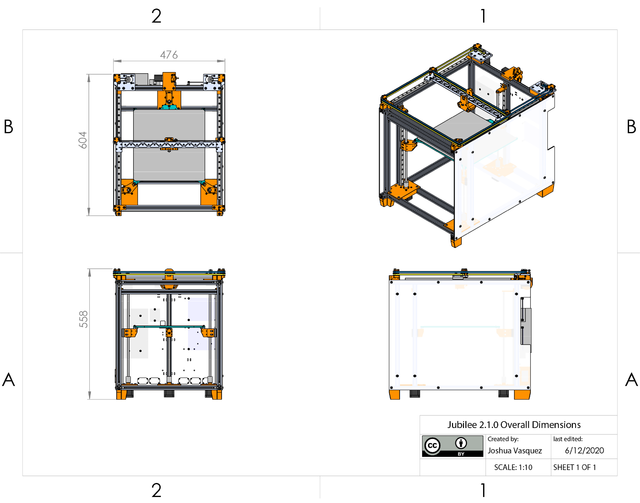

Overall Specs

Motion System Specs

- 300x300x300mm build space (with the default extruder). See the Build Volume Tool Relationship page for how tools change the effective build volume.

- All purchased parts called out in the V2 Shopping List.

- Designed such that the Z-axis can be adjusted to your liking with no changes to the XY frame or toolchanging setup.

- Core-XY layout for high-speed printing. Rapids of between 20000mm/min and 30000 mm/min depending on XY stepper motors and heatsinking options.

- Flush-Form CoreXY Belt Pattern. Upper and lower belts are laid out directly on top of each other, and belts only travel perpendicular to the frame. Belt-tensioning is done conveniently with two set-screws that adjust the motor locations along slots.

- Designed with Exact-Constraint machine-design principles where possible

- Kinematically coupled bed plate

- autotramming with 3-point bed-leveling (courtesy of the Duet)

- *Fabricatable.* Almost all fabricated parts are 3D printable. Printed parts are intentionally kept simple and minimize the use of support material. (Exceptions: the bed plate, crossbar, and toolchanger lock must be machined. See notes in the BOM for getting these parts made for cheap.)

- Metric fasteners everywhere.

- Documented with a comprehensive BOM and set of assembly instructions.

Tools and Tool-Changing

- 409mm of horizontal tool rack space, capable of holding 4 default extruder tools

- Detailed Space Specifications for adding custom tools presented in the Tool Interface Diagram (PDF).

- Automatic Toolchanging System compatible with both homebrew and E3D tool plates

- Sensored, torque-based locking system will lock down tool plates with a constant locking torque.

3D Printing

- Stellar print quality with direct-drive extruders. Jubilee can compete with systems at the $5K price range.

- Multicolor Printing possible *without* the need for a prime tower made possible by firmware-driven purge and wipe commands between tool changes. (This feature requires quite a bit of tuning to get working.)

- Slicer-agnostic. All the complexity of juggling tools is handled at the GCode firmware script level. Slicers need only change to a new tool by invoking a *T0*, *T1*, etc. command.

Extensibility

- User Extensible! Jubilee can accommodate custom tools and custom bed plates for specialized 3D-printing and uses beyond 3D printing. (See the Extending section)

Testing

- Cycle-tested. Jubilee has performed thousands of toolchanges flawlessly.

Pricing

- Self-Sourcing parts for Jubilee cost ~$1400 (US). The default extruder costs ~$200 each. We encourage community development for a wider spread of tools at different price points.

Legal

- Completely Open-Source with a CC-BY license. STLs, STEPs, and original Solidworks assemblies are included in the online project repository. Make use of the Jubilee design in ways that suit you.

Overall System Design

Read more about Jubilee's subsystem design and intended software behaviors in the links below.