Difference between revisions of "Lab Automation Plate"

Poofjunior (talk | contribs) |

Poofjunior (talk | contribs) |

||

| Line 19: | Line 19: | ||

=== 3D Printed Parts and Settings === | === 3D Printed Parts and Settings === | ||

| − | + | Print all parts with the following print settings: | |

| + | * PLA | ||

| + | * 0.4mm nozzle | ||

| + | * No supports | ||

| + | * 0.2mm layer height | ||

| + | * 6 perimeter layers (This is especially critical for parts that have heat-set inserts) | ||

| + | * 20% infill * printable in the provided orientations | ||

| + | * external perimeter first | ||

| + | * ''uncheck'' "Detect Thin Walls" if your Slicer has this settings. | ||

| + | ** Otherwise, small gaps will not be filled. | ||

| − | + | {| class="wikitable sortable" | |

| + | |- | ||

| + | ! Quantity !! Part Num !! Part Source !! Note | ||

| + | |- | ||

| + | | 1 || n/a || [https://github.com/machineagency/jubilee/blob/main/bed_plates/6x_well_plate_bed/fabrication_exports/stls/segmented_6_slot_bed_attachment.STL bed attachment] || | ||

| + | |} | ||

=== Laser Cut Parts and Settings === | === Laser Cut Parts and Settings === | ||

Revision as of 12:48, 28 September 2021

Overview and Specs

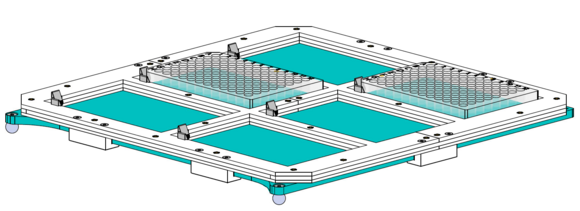

This bed plate holds up to six standard well plates in a repeatable position. It can be fabricated entirely from laser-cut, 3D-printed, and off-the shelf hardware, and it can be assembled with conventional hand tools.

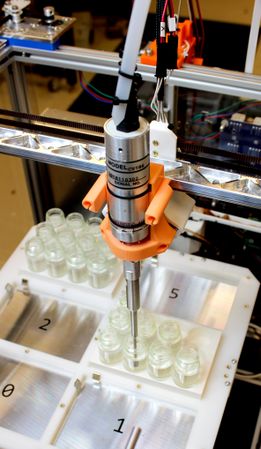

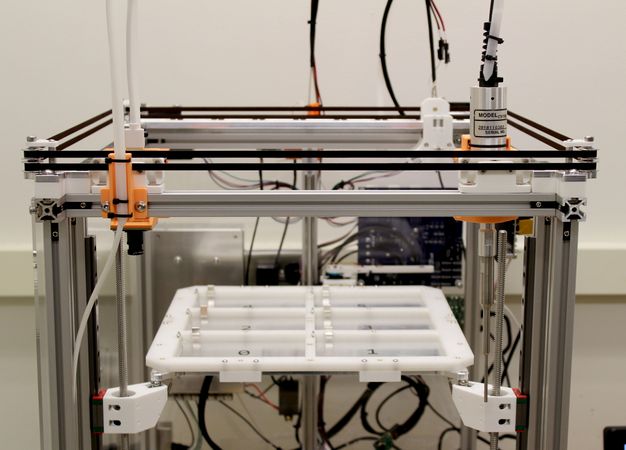

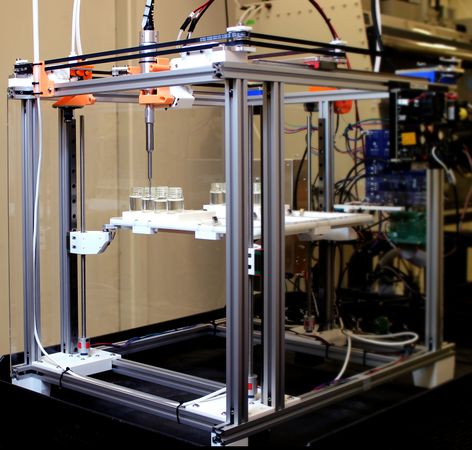

Here's a sample setup where Jubilee has been reconfigured with a Sonication horn to sonicate samples automatically:

Image Credit: Nadya Peek

Parts to Buy

Parts to Make (or Order)

3D Printed Parts and Settings

Print all parts with the following print settings:

- PLA

- 0.4mm nozzle

- No supports

- 0.2mm layer height

- 6 perimeter layers (This is especially critical for parts that have heat-set inserts)

- 20% infill * printable in the provided orientations

- external perimeter first

- uncheck "Detect Thin Walls" if your Slicer has this settings.

- Otherwise, small gaps will not be filled.

| Quantity | Part Num | Part Source | Note |

|---|---|---|---|

| 1 | n/a | bed attachment |

Laser Cut Parts and Settings

The following parts must be laser-cut from 3.175 mm (1/8th in.) Acetal Homopolymer, aka: Delrin. Delrin can be sourced in the United States in sheets of 12-in. x 24-in. from OnlineMetals.

If you are certain that your laser cutter applies automatic kerf compensation (rare), cut the original DXFs. Otherwise, cut the offset DXFs. (If you are uncertain, cut the offset DXFs.)

To download the file, right click, and select "Save Link As."

| Quantity | Name | Original DXF | Offset DXF |

|---|---|---|---|

| 1 | Top Layer Upper Plate | Original | Offset |

| 1 | Top Layer Lower Plate | Original | Offset |

| 1 | Middle Layer Upper Plate | Original | Offset |

| 1 | Middle Layer Lower Plate | Original | Offset |

| 1 | Middle Layer Center Plate | Original | Offset |

| 1 | Middle Layer Left Plate | Original | Offset |

| 1 | Middle Layer Right Plate | Original | Offset |

| 1 | Bottom Layer Upper Plate | Original | Offset |

| 1 | Bottom Layer Lower Plate | Original | Offset |

Assembly Tools

Assembly Instructions

- [Lab Automation Plate Assembly Instructions]

Software

Since Jubilee uses 3-point bed leveling to home the Z axis, you will need to adjust the three test points in your bed.g config file. The suggested locations are:

TODO

Furthermore, you'll want to home the machine before installing any labware. Otherwise Jubilee's carriage will collide with it during the homing sequence.

Apart from that, no other software changes are needed for this bed plate.